Library

Library

Manufactured Products

A manufactered product is where a product is automatically created from another product(s). If you sell whole pizzas, these might be one product in the Point of Sale; if you also sell individual slives by cutting a whole pizza into slices, then the slices are manufactured from the whole pizzas automatically.

There are two main types of manufacturing, assmebly manufacturing where one or more components are added together to create another product; and split manufacturing where one product is split into multiple items.

Manufacturing within Fieldpine is designed for simple use cases, it is not featured enough to handle the more complex requirements of meals or cooking.

Assembly Manufacturing

Assembly manufacturing is where one or more component products are used to create an output product. A 'deluxe ski package' might be manufactured from

- 8 hours of ski instructor time

- 4 helicopter rides

- 2 all mountain ski passes

- 1 bottle of Sparkling wine

- 2 gourmet lunches at Mountain top cafe

Split Manufacturing

Split manufacturing is where an item is created by breaking up another product in a non reversable way. The pizza example covers this, you make and count whole pizzas, but you might choose to split manufacture 'pizza slices' by breaking a single pizza into say 6 slices.

Controlling Manufacturing

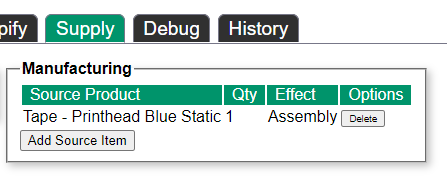

To setup or edit manufacturing, edit the target manufactured product (the 'deluxe ski package' or 'pizza slice' products), switch to the supply tab and use the manufacturing controls.

An example of a product being manufactured from a single other product. Single product might be used where the target product

is being rebranded in some way.

An example of a product being manufactured from a single other product. Single product might be used where the target product

is being rebranded in some way.

Example - Box & Reams of Paper

Paper is typically packaged into reams, but is also commonly sold in a box of 5 reams. As a retailer, you might sell a ream for $5, and a box of 5 reams for $20.

Within Fieldpine there are several ways you can handle this depending on how complex you wish to get.

Option A - Seperate Products

- Create a product definition of a ream and set the price to $5

- Create a product definition for a box and set the price to $20

- Add barcodes for the ream and box (qty=1 in both cases) pointing to the respective products. Typically the box of 5 barcode is different to the individual ream barcode

- When selling, scan what is being sold. If the customer buys 5 individual reams, they will be charged 5x $5 = $25.

- Stock comtrol is two seperate items, boxes and reams

Option B - One product, seperate barcodes

- Create a product definition for the ream and set the price to $5.

- Create a quantity discount pricing rule, for 5x = $20

- Add the barcode for the ream, as qty=1

- Add the barcode for the box as qty=5

- When selling, if a customer buys 5 individual reams, they will be charged $20, as the quantity discount price rule will fire

- If you scan a box, the sale will say 5x reams and charge $20. You only need to scan once, the POS will automatically adjust the quantity to 5

- Stock control is in reams

Option C - Split Manufacturing

- Create the product defintion for a box, and set the price to $20

- Create the product definition for a ream, and in tbe manufacturing definition, make this product split manufactured from the box.

- Add the barcode, both qty=1, for the respective products.

- When selling, if you scan/sell a ream, the POS will automatically subtract 1 box from stock and create 5 reams in stock. You can then sell additional reams until none remain, at which point the POS will split another box and the process repeats.

- Stock control is counted in terms of "boxs of paper", not individual reams, (other than the few current split reams)

Option D - Assembly Manufacturing

- Create the product definition for a ream, and set the price to $5

- Create the product defintion for a box, and set the price to $20. In the manufacturing section make this product assembly manufactured from 5 reams

- Add the barcode, both qty=1, for the respective products.

- When selling, if you scan/sell a box, the POS will automatically subtract 5 reams from stock.

- Stock control is counted in terms of reams